Cold-Rolled Steel: Pinnacle of steel

Strong yet smooth steel, enhancing everyday convenience

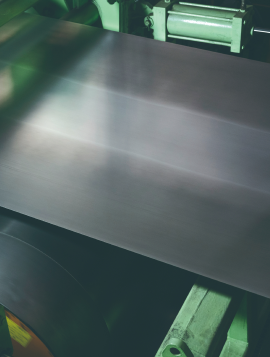

Cold Rolled Steel requires the most delicate technology and high-quality processing among steel products. Hyundai Steel’s Cold Rolled Steel Plate can boast high strength and excellent surface quality, used in various fields such as automobiles, appliances, and building materials. Cold rolled products are processed at room temperature to produce thin, highly durable steel sheets that maximize corrosion resistance and workability, resulting in high added value. Through the advanced facilities of the Dangjin Steelworks and the Suncheon Plant, which produce more than 6 million tons of Cold Rolled Steel annually, we are leading the development of ultra-high-strength steel plate in response to the automotive industry’s demand for lightweight materials, contributing to the production of lightweight and strong vehicles. Hyundai Steel is securing competitiveness in the global market with high-quality Cold Rolled Steel tailored to customer demands.

-

-

6 million tons

per year -

Global cold rolled

production capacity

-

6 million tons

-

-

5th in

the world -

Automotive steel plate

production capacity

-

5th in

-

- Advanced production systems and

innovative processes - Establishment of state-of-the-art equipment and continuous investment, performance enhancement through new methods, and development of 3rd generation steel

- Advanced production systems and

Key products

Pickling & Oiling Coil

Pickling & Oiling Coil is a product that has had its surface contaminants and iron oxide removed using hydrochloric acid, followed by an oil treatment to prevent oxidation. It is mainly used as material for automobiles, construction materials, and pipes.

Key specifications

| Hyundai Steel | SPHC, SAPH400, SPFH590 |

|---|---|

| JIS | SPHC, SPHD, SPHE |

| ASTM | ASTM A1011 |

| EN | DD11, DD13, S355MC, S420MC |

Cold Rolled Coil

Cold Rolled Coil (CR) is a product that has achieved good workability and a smooth surface through pickling, cold rolling, and heat treatment processes. The biggest difference compared to hot rolled products is that it lacks an oxide layer on the surface, and it is used in various applications such as appliances, welding rods, and automotive inner and outer panels.

Key specifications

| Hyundai Steel | SPCC, SPCEN, SPRC340, SPFC590DP |

|---|---|

| JIS | SPCC, SPFC340, SPFC780Y |

| ASTM | ASTM A1008 |

| EN | DC01, HX220YD, HC340LA, HCT590X |

Electro-Galvanized Coil

Electro-Galvanized Coil (EG) is a product where zinc is applied to cold rolled coil through electro-galvanization, offering excellent corrosion resistance and workability. It is mainly used as a material for appliances such as televisions, refrigerators and washing machines.

Key specifications

| Hyundai Steel | SECC, SECEN, SEFC340 |

|---|---|

| JIS | SECC, SECE, SEFC440 |

| EN | DC01+ZE, DC03+ZE |

Aluminum-Silicon Coated Coil

Aluminum-Silicon Coated Coil (ALS) is a product where aluminum is coated on the surface of cold rolled coil, offering superior heat resistance compared to galvanized coil and cold rolled coil. Afterwards, it is supplied as material for hot stamping, widely used for lightweight products in the automotive sector.

Key specifications

| Hyundai Steel | SACC, SACD, SABC980, SABC1470 |

|---|---|

| JIS | SA1C, SA1D, SA1E |

| EN | DX51D+AS, DX53D+AS |

Application areas

Hyundai Steel’s cold rolled products offer lightweight and corrosion-resistant solutions that meet customer requirements with excellent surface quality and high processability in various industries. Our products serve as key materials in sectors such as automotive and appliances, maximizing product durability and performance while contributing to the efficiency of manufacturing processes.

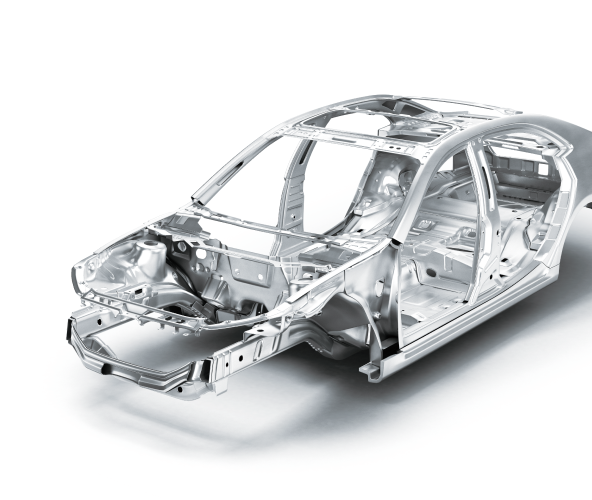

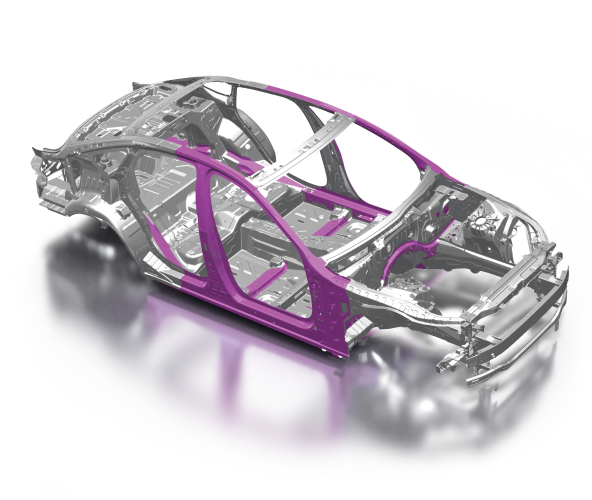

Automotive sector

- Lighter and more durable

- Applied to the exterior panels, frames, and structures of vehicles, providing lightweight design and high durability. With excellent formability and superior surface quality, it ensures vehicle design and stability, while enhanced corrosion resistance extends the vehicle's lifespan and increases safety.

SGACUD-E, SGARC340BH-E,SGAFC1180Y, SGAFC980Y, SPFC1470Y, SPFC1180Y, SPCC-DF, SPFH980-P, SABC1470, SABC1760

Hyundai Steel H-SolutionAppliance sector

- Excellent corrosion resistance and high-quality finish

- Applied to the exterior materials and internal components of appliance, it provides durability and a high-quality finish. It is resistant to corrosion and meets both design and performance requirements with its beautiful surface treatment. It enhances the performance of various appliances while maintaining the luxury and durability of the product.

SECC, SGCC, SGCD, SGC295Y

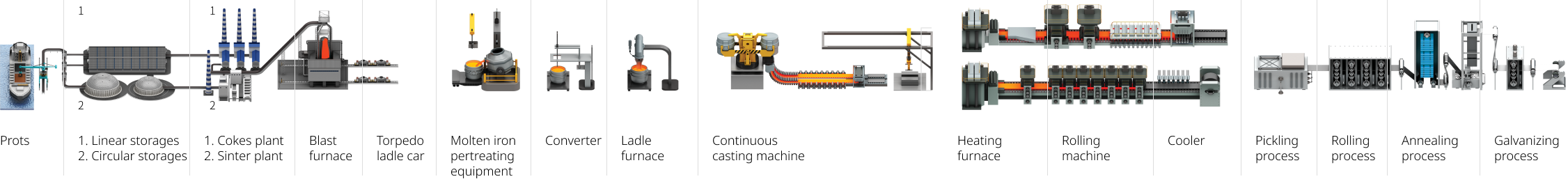

Manufacturing process

Cold Rolled Steel manufacturing process

The manufacturing process involves cold rolling the Hot Rolled Steel at room temperature to achieve the desired thickness.

First, the Hot Rolled Steel Plates are pickled to remove surface oxides, and then cold rolling is performed to produce thin and uniform steel sheets.

Afterwards, the material undergoes a heat treatment (annealing) process to adjust its strength, and if necessary, surface coating (such as zinc or aluminum)

is applied to enhance corrosion resistance and workability. Through this process, Cold Rolled Steel Plates are completed as products with high surface quality

and precise thickness, suitable for use in various industries.

Hynndai Steel's intergrated steelworks manufacture hot-rolled and cold-rolled coils, heavy plates, pipes, and lightweight automotive parts out of iron ore and coal. By melting lumps of raw materials, molten metal is generated in blast furnaces, after which it is purified in the steelmaking process and then goes on to the continuous casting process to make slabs that can also be hardened half-finished products. Those of slabs are thoroughly rolled at a high temperature (above 1,100℃) in order to make hot-rolled coils. After that, the cold-rolled coils are made by rolling the HRC (hot-rolled coils) at room temperature to process for final usage, which is mainly for lightweight automotive parts.

Hyundai Steel’s electric arc furnace uses steel scrap to manufacture sections, reinforcing bars, and railway rails that are used for buildings, bridges and railways. After melting the steel scrap to make molten metal, it is then smelted to eliminate impurities before proceeding to the continuous casting process to manufacture halffinished products, such as blooms and billets. These half-finished products can be rolled by reheating to increase their size as finished products, such as sections and reinforcing bars, in various sizes and thickness.