R&D

Introducing Hyundai Steel’s R&D strategy and trends

that drive innovation in steel beyond limits

Core strategies

Hyundai Steel R&D Center has established the mission of “Leading innovation ahead of the crossroads of change,” and has derived four core strategies to create new value for sustainable growth.

carbon emission reduction products and technologies

The era of carbon neutrality

To mitigate risks from climate change such as global warming and rising sea levels, the world declared carbon neutrality through the Paris Agreement in 2015.

And recently countries, particularly in Europe and the United States, have proposed policies such as carbon border taxes and clean competition act.

South Korea has established a carbon neutrality national strategy to reduce greenhouse gases by 40% compared to 2018 levels by 2030 and is planning to promote

the purchase of 4.5 million electric and hydrogen vehicles by 2030.

Establishing a Production System Based on Hydrogen-Reduced Ironmaking and Next-Generation Electric Arc Furnace

Hyundai Steel’s R&D Center is pursuing two key strategies: developing low-emission products and reducing emissions across our processes. To achieve this, we are developing technologies that enable production of premium, low-emission steel through hydrogen-based direct reduction and the use of new electric arc furnaces.

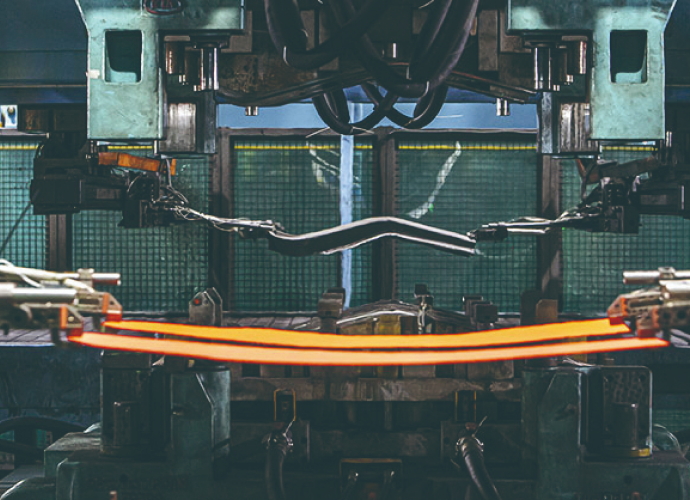

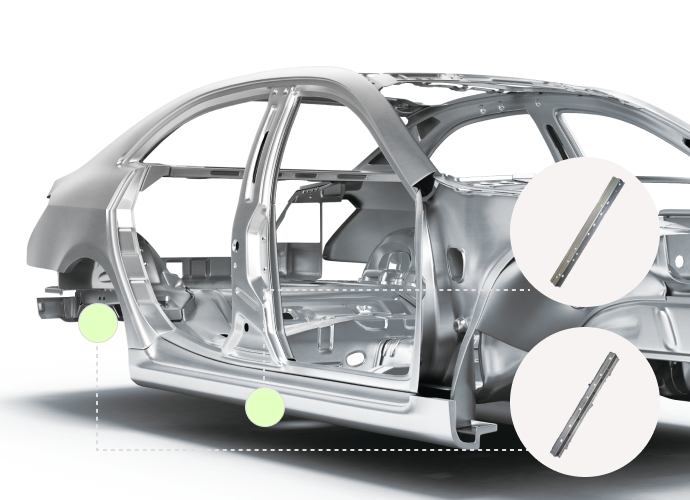

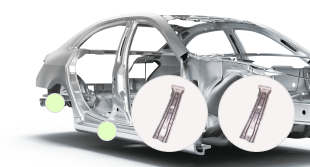

Advancing product production using the Electric Arc Furnace–Blast Furnace Hybrid Process

The Electric Arc Furnace–Blast Furnace Hybrid Process serves as a preliminary stage for next-generation electric arc furnace-based production. This process mixes molten iron produced from both electric arc furnaces and blast furnaces, significantly reducing carbon emissions compared to conventional blast furnace methods. Hyundai Steel R&D Center is taking the lead in pilot production using the hybrid process for a variety of products traditionally manufactured through the blast furnace method. Products produced via this hybrid process undergo comprehensive evaluations, including basic material properties (chemical composition, tensile/bending tests), application properties (formability, weldability, paintability), and final component performance assessments. Currently, the hybrid process has demonstrated equivalent quality and performance levels to conventional blast furnace products for several items, including automotive steel sheets and corrosion-resistant heavy plates. Moving forward, Hyundai Steel plans to continuously expand the coverage of carbon emission reduction products through ongoing development efforts.

-

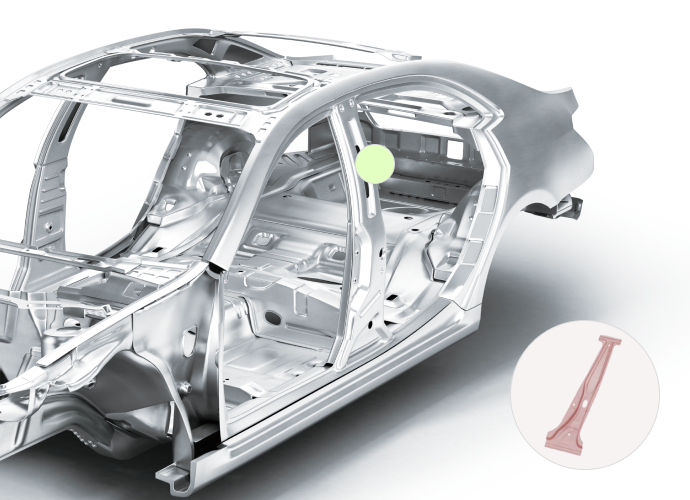

- 1.5GPa-Class Hot Stamping (SABC1470)

- Favorable results in weldability, durability, and hydrogen embrittlement evaluations

Favorable results in crash simulation evaluations

-

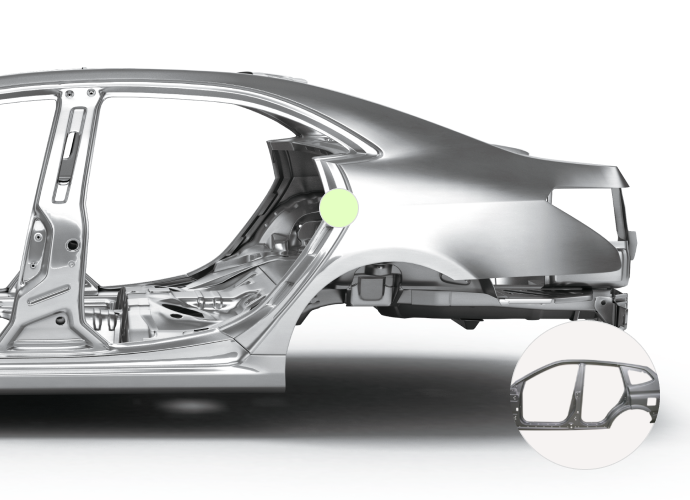

- High-formability outer panel material (SGACUD-E)

-

Good formability (Limit Drawing Ratio (LDR), Forming Limit Curve (FLC), etc.)

Favorable results in weldability and paintability evaluations, among others

-

- 780MPa-Class Hot-Rolled Ultra-High-Strength Steel (SPFH780-P)

-

Favorable results in durability limit evaluations

Favorable results in formability (Hole Expansion Ratio, HER) and laser

welding evaluations, among others

-

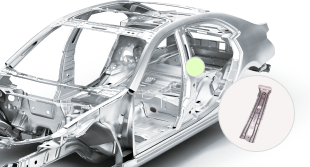

- 1.2GPa-Class Cold-Rolled Ultra-High-Strength Steel (SP(GA)FC1180Y)

- Internal evaluations for formability and welding in progress

Development of reduction-carbon tire cord steel

Tire cord steel is composed of ultra-fine wires, and strict control of non-metallic inclusions within the steel is essential to refine wire rods and enhance tire quality. Steel with residual elements that could cause non-metallic inclusions controlled to the extreme is referred to as high-cleanliness steel, and it is typically produced using molten iron from blast furnaces. Hyundai Steel R&D Center is developing high-performance, high-cleanliness tire cord steel with reduced carbon emissions compared to conventional blast furnace products by utilizing the Electric Arc Furnace–Blast Furnace Hybrid Process.

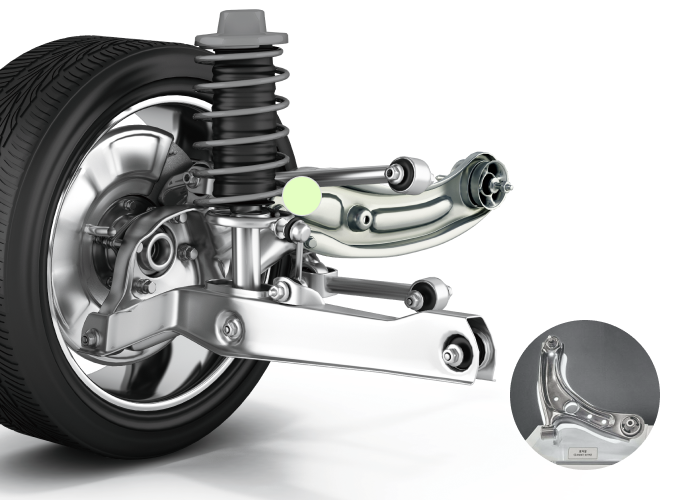

Materials and components for future mobility

Change in the mobility paradigm

The electrification of vehicles is the most critical trend in the rapidly changing automotive industry. If the current challenges facing the electric vehicle

industry, such as bridging the price gap with internal combustion engine vehicles, battery technology, and charging infrastructure issues, are resolved, the

growth of the electric vehicle market will accelerate significantly.

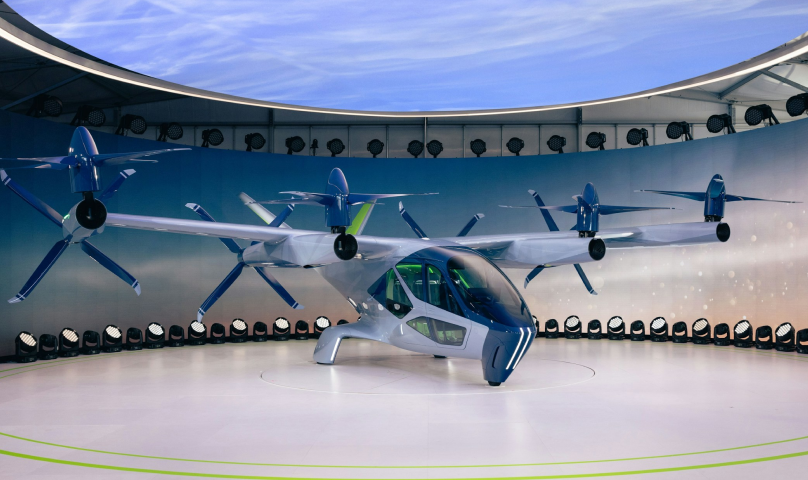

The advancement of autonomous driving technology is accelerating the emergence of new mobility solutions that have not been experienced before. Advanced Air

Mobility (AAM) based on self-driving technology is set to greatly change human life, and numerous demonstration flights and practical projects are currently

underway. Hyundai Motor Group is showcasing the PBV concept that can be used as hubs and docking stations, connecting AAM with ground mobility and offering

various services to present a new mobility lifestyle

Execution of the group’s future mobility strategy

Hyundai Steel R&D Center is responding to the evolving mobility industry and implementing the group’s future mobility strategy by developing key materials for electric vehicles and hydrogen fuel cell vehicles, such as magnetic powders for drive motors and separator plates, as well as conducting research on the componentization of PBV and AAM bodies.

- Drive Train

-

Metal separator plates

Electrolysis separator plates

-

- High-Performance Steel Materials

- Customized steel component for next-

generation mobility (PBV, seats)

-

- CFRP/GFRP

-

High-Speed Manufacturing Technology for

AAM and Aircraft components

Smart Factory

Data-driven manufacturing process advancement

In the past, steel manufacturing processes were primarily operated based on experience and expertise. However, in recent years, steel companies have been

actively adopting cutting-edge technologies such as big data and artificial intelligence (AI).

Through a big data platform, each data is connected to provide information needed for decision making. By integrating AI with this big data, steel

manufacturing processes can be further advanced and optimized.

Enhancing steel manufacturing competitiveness through digital transformation

Hyundai Steel R&D Center has established and is implementing a roadmap for smart factory development across all its facilities. The R&D Center also focuses on creating programs to enhance the digital capabilities of its employees. By realizing and expanding smart factory outcomes, Hyundai Steel aims to maximize the benefits of smart factory implementation and contribute to strengthening the core manufacturing competitiveness of the steel industry.

-

-

Infrastructure

development -

Big data platform

Product development system

Supercomputing

-

Infrastructure

-

-

Process and

workflow optimization -

Optimization of operations and

scheduling

Process improvements utilizing

artificial intelligence

-

Process and

-

- Future technologies

-

Automation with robotics

Computational material analysis