Hot-Rolled Steel: ABCs of steel

Delivering high-quality hot-rolled solutions powered by an integrated steelmaking system and cutting-edge facilities

Hot Rolled Steel is a product made by hot rolling a semi-finished slab into coil form. Hyundai Steel produces 9.1 million tons of high-quality Hot Rolled Steel through its consistent steel production system and state-of-the-art equipment. Hot Rolled Steel Plates produced by Hyundai Steel range in thickness from 1.2 mm to 25.4 mm and are used in various industries, including automotive, structural, and steel pipe applications.

-

- 9.1 million tons per year

- Stable supply capability

-

- State-of-the-art equipment

- High-quality integrated production system

-

- Customer-specific solutions

- Providing fast delivery through a flexible production system optimized for the specific needs of various industries

Key products

Hot Rolled Steel for structures

Structural steel is one of the most commonly supplied and widely used materials across various industries. It is used in construction sites for formwork, steel mesh and fire shutters and in general structures with lenient surface or material standards, such as streetlights, deck plates and processed section.

Key specifications

| KS | SS275, SS315, SS410, SS450, SM275A/B, SM355A/B/C/D, SM420A/B/C/D |

|---|---|

| JIS | SS330, SS400, SS490, SS540, SM400A/B, SM490A/B/C, SM490YA/YB, SM520B, SN400B, SN490B |

| ASTM | A36, A283-C, A1011CS Type B, A1011SS Gr.33, A1011SS Gr.40, A1011HS Gr.50, A1011HS Gr.55, A1018HS Gr.50, A1018SS Gr.36 Type2 |

| EN | S235JR, S275JR/J0/J2, S355JR/J0/J2 |

Hot Rolled Steel for cold rolled steel

Hot rolled steel for cold rolling is processed into various cold-rolled products such as CR (Cold Rolled Coil), GA (Galvannealed Coil), GI (Galvanized Coil), and EG (Electro-Galvanized Coil) through heat treatment and coating processes.

Key specifications

| JIS | SPHC, SPHD, SPHE, SAPH370, SAPH400, SAPH440, SPFH540, SPFH590 |

|---|---|

| SAE | SAE1006-102 |

Hot Rolled Steel for pipes

Hot rolled steel for pipes offers excellent weldability and formability by optimizing its chemical composition and rolling temperature during the steelmaking and rolling processes. It is classified into several categories, including general-purpose, mechanical structures, heat exchangers, earthquake-resistant, pipelines, and casing/tubing applications. It is primarily used for general steel pipes, conduits, and boilers.

Key specifications

| Hyundai Steel | HPCD340A, HPCD410A, HPCD440A, HPCD470AH, HS1470DIB, HS35B20 |

|---|---|

| JIS | SPHT1/2/3, STK400, STK490, STK500, STK540, STKM11A/12B/13A/13B/15A, STKN490B, STKT590 |

| API | J55, K55, P110, 5L-B, X42, X46, X52, X56, X60, X65, X70, X80 |

Hot Rolled Steel for automobiles

Hot Rolled Steel for automobiles is used for various applications, including the inner and outer panels of commercial vehicles and special vehicles, as well as parts for seat belts and vehicle accessories. Hot Rolled Steel is more frequently processed into Cold Rolled Steel for automotive applications rather than being used directly in its hot rolled form.

Key specifications

| JIS | HS540AS, HS590AS, HS780AS |

|---|---|

| SAE | SAPH310, SAPH370, SAPH400, SAPH440, SPFH540, SPFH590 |

High Carbon/Alloy Steel

These are products with a carbon content of 0.3% to 0.6% or a carbon content of 0.15% or higher with added alloying elements. Since resistance to repetitive work and friction is required, a large amount of carbon and alloying elements are added to achieve high strength, high hardness, and wear resistance. It is mainly used for special applications such as automotive parts, chains, blades, and tools.

Key specifications

| Hyundai Steel | S20C, SAE1050M, SAE1055M |

|---|---|

| JIS | S45C, S50C, S53C, S55C, SK60M, SK85, SNCM220, SCM415, SCM430, SCM435 |

| SAE | SAE1035, SAE1070, SAE1552 |

| EN | EN-C45 |

| DIN | 16MnCr5, 51CrV4 |

Patterned Steel Plate

Checkered plate is hot rolled steel with embossed patterns and is commonly used for steps and flooring in buildings. The patterns are categorized into Pattern A and Pattern B. Pattern A is commonly used in Southeast Asia and the Middle East, while Pattern B is preferred in the Americas, including the United States and Mexico.

| Peak height | Peak length | Peak width | Peak pitch | |

|---|---|---|---|---|

| Pattern A | 0.6~1.2 | 30 | 7.3~7.5 | 36~38 |

| Pattern B | 0.6~1.2 | 25 | 7.1~8.4 | 32~34 |

Key specifications

| Hyundai Steel | HS300CHK, HS400CHK |

|---|

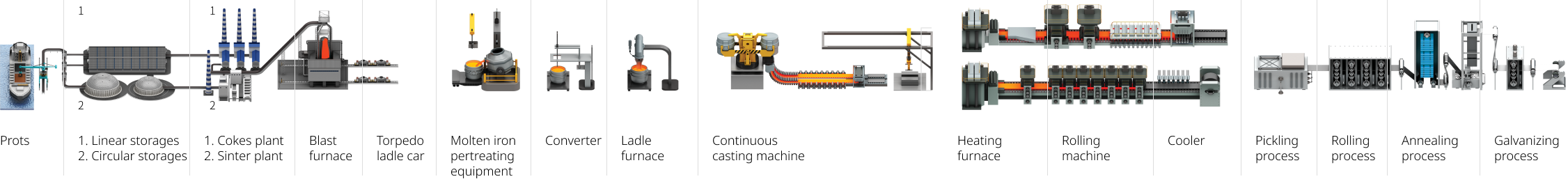

Manufacturing process

Hot Rolled Steel manufacturing process

The hot rolling process involves rolling semi-finished slabs produced from the continuous casting process to manufacture hot rolled steel sheets. The slabs are uniformly heated in a reheating furnace and then rolled to the appropriate thickness and width through the roughing rolling process, where shape correction is also performed. In the finishing rolling process, the slabs are further rolled to meet the precise dimensions required by customers. After rolling, the steel undergoes controlled cooling with water to secure the desired mechanical properties. Finally, it is coiled to facilitate storage and transportation.

Hynndai Steel's intergrated steelworks manufacture hot-rolled and cold-rolled coils, heavy plates, pipes, and lightweight automotive parts out of iron ore and coal. By melting lumps of raw materials, molten metal is generated in blast furnaces, after which it is purified in the steelmaking process and then goes on to the continuous casting process to make slabs that can also be hardened half-finished products. Those of slabs are thoroughly rolled at a high temperature (above 1,100℃) in order to make hot-rolled coils. After that, the cold-rolled coils are made by rolling the HRC (hot-rolled coils) at room temperature to process for final usage, which is mainly for lightweight automotive parts.

Hyundai Steel’s electric arc furnace uses steel scrap to manufacture sections, reinforcing bars, and railway rails that are used for buildings, bridges and railways. After melting the steel scrap to make molten metal, it is then smelted to eliminate impurities before proceeding to the continuous casting process to manufacture halffinished products, such as blooms and billets. These half-finished products can be rolled by reheating to increase their size as finished products, such as sections and reinforcing bars, in various sizes and thickness.