Product & Technology

Driving a new era of steel with a resource-circulating production system

Global leadership

-

24 million tons per year 70 years of electric furnace

24 million tons per year 70 years of electric furnace

technology (12 million tons

from electric furnaces) -

Automotive material

Automotive material

specialized steelworks -

The largest number of

The largest number of

world-class products

in the country

Sustainable innovation

Key products

Hyundai Steel offers steel solutions that are optimized for the industry, featuring high strength, lightweight, and durability.

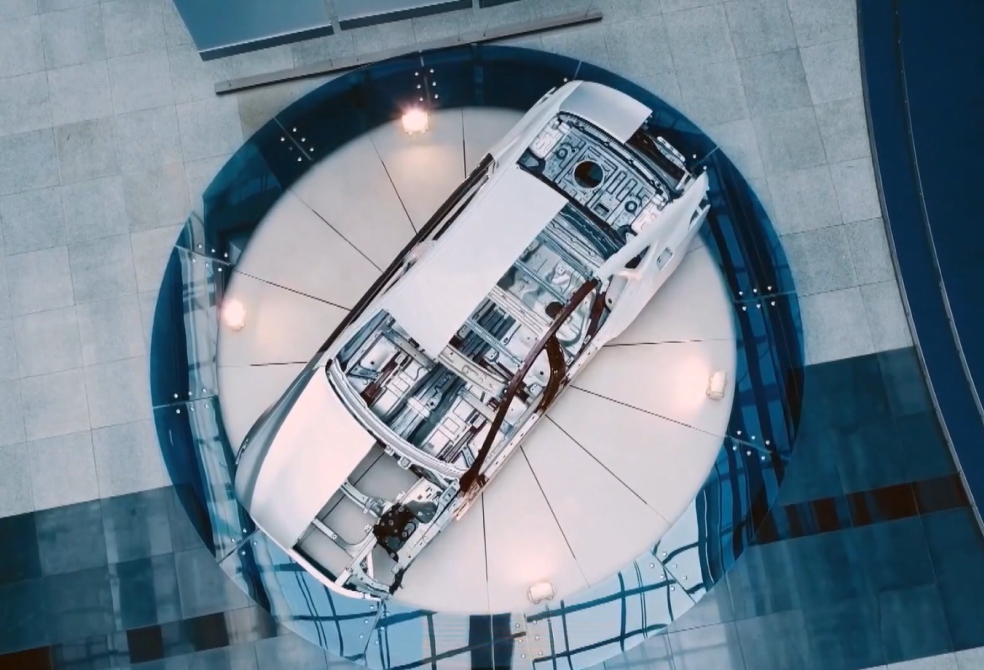

Automobile

Lightweight and safe vehicles are the top priority for all automobile manufacturers. Hyundai Steel is focusing on the development of technologies

that ensure both high strength and workability, taking into account the properties of steel that become harder as its strength increases.

As a result, it has become a specialized steel mill for automotive materials, producing automotive inner and outer panels, lightweight components

and special steels known as the "Pinnacle of steel".

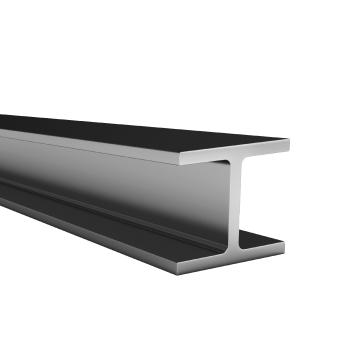

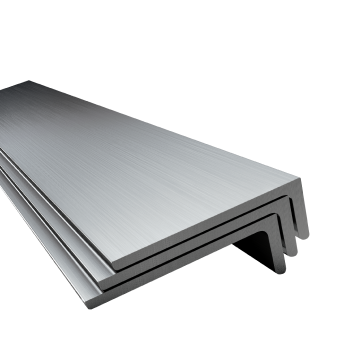

Construction

In the construction sector, such as buildings and bridges, steel materials are essential elements. Typical steel materials that primarily serve as

the framework of buildings and are responsible for the safety of structures include H-sections and rebar. In addition, thick plates are used in the

construction of large bridges, such as the Bosphorus Bridge in Turkey.

Hyundai Steel is proactively developing and supplying products suitable for high-rise buildings and enhanced seismic standards, based on its

know-how as the number one player in the domestic market share of bar steel maintained for decades.

Energy

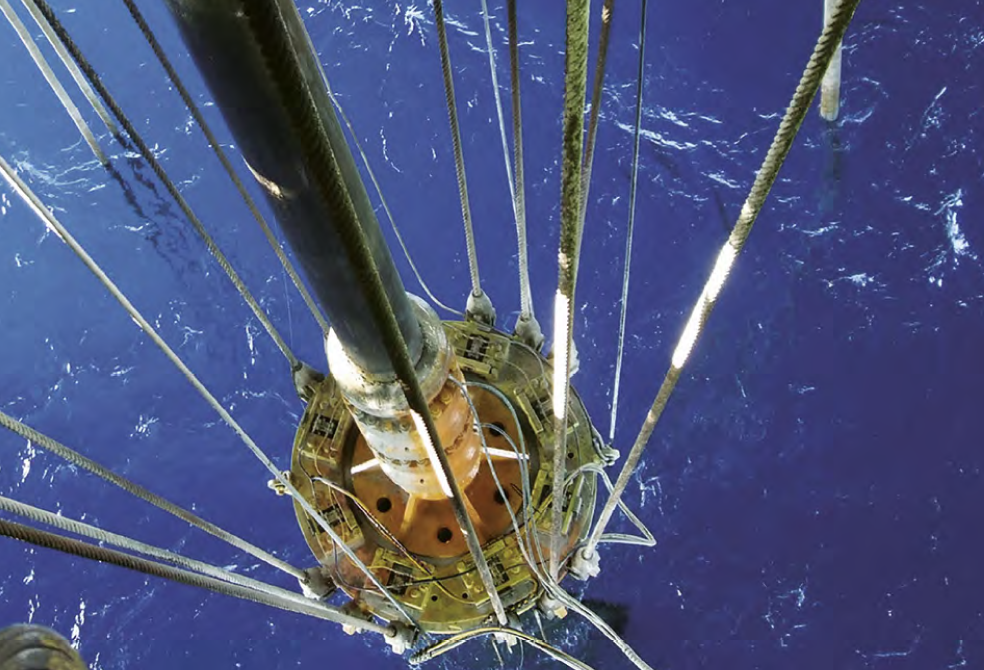

To obtain energy resources such as oil and gas, countries around the world are conducting extraction activities in harsh environments. Shale gas

buried more than twice as deep as before, or crude oil extracted from extreme temperature environments such as the Arctic and deep seas, is

transported using pipelines or large transport vessels constructed in regions like the Siberian plains and deserts.

To withstand such environments, steel materials are required to have high strength, impact resistance, and corrosion resistance. As the operating

environment for energy steel becomes harsher, Hyundai Steel is focusing on enhancing the stability and efficiency of its products.

Home appliances

Iron is ubiquitous in everyday life, including refrigerators, washing machines, televisions and dishwashers. As part of people's daily lives, the

steel used in appliances and kitchenware requires high design perfection, from elegant appearance to excellent workability. In addition, it must be

thin, light, and exhibit high corrosion and heat resistance.

Hyundai Steel provides high-quality steel products for home appliances through advanced equipment and techniques, contributing to enhancing the

competitiveness of the home appliance industry.

Shipbuilding

With the emphasis on efficiency and economy, the demand for larger and lighter ships is increasing. In addition, the number of vessels operating in

polar regions, traversing between Antarctica and the Arctic, is also increasing to shorten routes. Steel used in this shipbuilding industry requires

advanced technology that can withstand extreme environments, including impact resistance, low-temperature toughness, and high strength.

To achieve this, Hyundai Steel holds classification certifications recognized by the world's top 10 classification societies.

Others

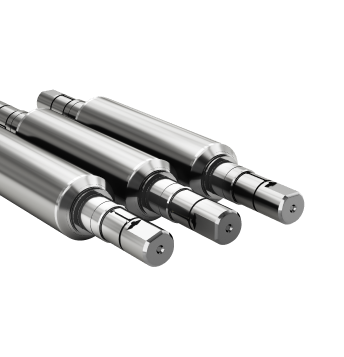

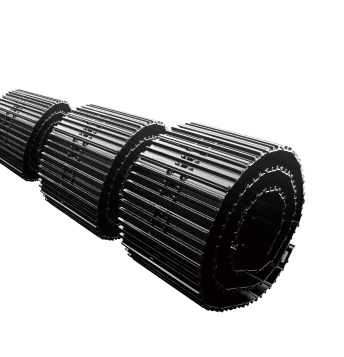

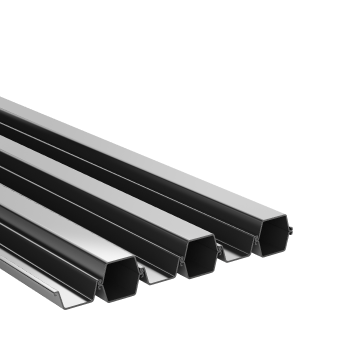

Rails for high-speed trains, excavators at construction sites, rolls for rolling steel materials, and steel sheet piles for foundation construction.

These four fields commonly involve products used in environments with high heat, pressure, and continuous friction. Therefore, high strength is

fundamental, and technologies focused on improving wear resistance and durability are essential. Hyundai Steel has continuously developed the first

in Korea and world-class products based on its long-standing know-how in the electric arc furnace process.

Hyundai Steel brand

With innovative technology and quality, we realize new possibilities in various fields such as automotive, construction, and energy.

World-class products

Hyundai Steel, as a steelmaker with the largest number of world-class products, is recognized for its high competitiveness and quality in the global market.