Safety & Health: Hyundai-Steel One Safety

Hyundai Steel strives to ensure the health and safety of the company and its stakeholders with the goal of becoming a safe steelworks for the next 100 years

Hyundai Steel’s health and safety objectives and management policy

| Vision | Realizing safe steelworks for 100 years |

|---|---|

| Objectives | Zero serious injuries and fatal accidents |

| Management Policy |

|

Occupational health and safety policy

Hyundai Steel is leading the spread of safety culture based on the vision of “Realizing Safe Steelworks for 100 Years” and the safety management slogan “H-S.O.S (Hyundai-Steel One Safety),” which aims to improve safety culture. In addition, we are enhancing safety capabilities and improving our health and safety management system through various occupational health and safety activities. On this basis, we have obtained ISO 45001 certification for the international occupational health and safety management system standard established by the International Organization for Standardization (ISO) and the International Labor Organization (ILO) at all domestic facilities, including the Incheon Plant, Pohang Plant, Dangjin Steelworks, Suncheon Plant, and Pangyo Office.

Occupational health and safety promotion strategy

| Purpose |

Improvement of safety levels through the implementation of key strategies for enhancing safety culture (establishment of safety management slogan, practical tasks) |

|---|---|

| Slogan |

|

| H-S.O.S Inherent Meaning |

|

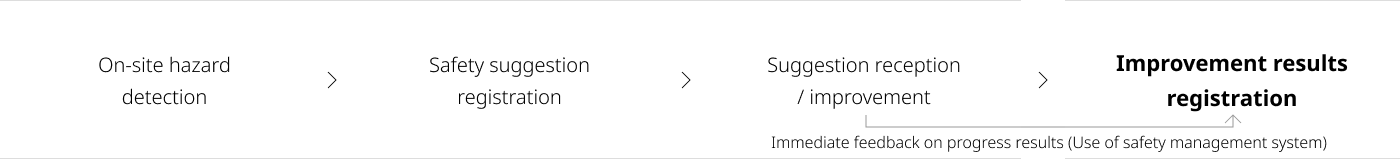

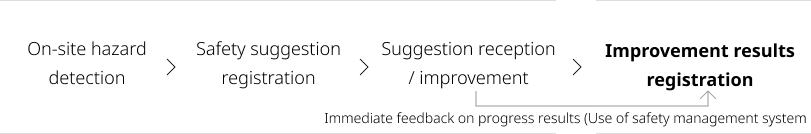

Promoting safety suggestion platform

Hyundai Steel is engaged in various activities to ensure a safe workplace, among which the ‘Safety Reporting System’ is the most representative initiative. All workers, including employees of the company, subsidiaries, and partners working at the sites, can directly propose various safety improvement suggestions such as the installation of safety facilities, changes in work procedures, improvements to the work environment, and organization through the safety management website.

- A total of 2,845

- Suggestions received (2023)

- 93%

- Improvements completed

Safety suggestion platform operation orocedure

-

- 현장 위험 발견

- 안전제안 등록

- 제안 접수/개선

-

진행결과 즉각 피드백

(안전관리 시스템 활용) - 개선결과 등록

Occupational Safety and Health Education

Internalization of Safety Education

To internalize safety education, Hyundai Steel utilizes a dedicated training venue equipped with audio-visual training equipment and provides expert courses to improve the capability of safety and health education instructors. We provide safety education programs for leaders and education on safety laws and regulations, our safety system, utilization of the safety computer system, and risk identification and improvement measures to help employees carry out their safety and health duties efficiently. In addition, we have enhanced the experience facilities of the Centennial Safety Culture Center located in the Dangjin Integrated Steelworks and developed new education courses aimed at further strengthening the safety capabilities of our employees

Emergency Response Training and Simulation training

Hyundai Steel has established a safety and health emergency preparedness and response plan for all operations and strives to minimize human and property damages by responding immediately in the event of an emergency. Safety training is conducted from time to time regarding safety, fires, explosions, and other accidents, and drills based on emergency scenarios are conducted at least once a quarter. In an emergency, the head of the safety and health department oversees the entire situation, including on-site command and victim relief, and each department head takes urgent actions in accordance with emergency response procedures to prevent the damage from expanding. After the emergency situation concludes, we develop and implement a recovery plan and systematically manage the emergency response system by reviewing measures to prevent recurrence and reviewing improvements on emergency response procedures.

Safety Education Status

| Category | Education program name | Subject | Frequency | Attendance rate |

|---|---|---|---|---|

| Legally mandatory education | Regular Safety Education | All Employees | Quarterly | 100% |

| Legally mandatory education | Supervisor Education | Leaders | Once a year | 100% |

| Legally mandatory education | Onboarding Education | New hires | When newly hired | 100% |

| Legally mandatory education | Special Safety Education | People performing hazardous work | When a task occurs | 100% |

| Legally mandatory education | Hazardous Chemical Education | Related personnel, Personnel managing chemicals | Once a year, Once every two years | 100% |

| In-house education | Advanced Supervisor Course, etc. | Applicants | On-demand | 100% |

Occupational Safety and Health for Suppliers

Support and Participation for Safety and Health Management of Suppliers

Hyundai Steel is supporting its suppliers in an effort to realize win-win safety management. In order to assist our suppliers in strengthening their safety and health infrastructure, we offer various supports, including financial assistance for hiring safety personnel, provision of safety education, reinforcing management, and construction of rest and sanitation facilities. We can monitor the entry and exit status of all workers at our business sites, including those from our supplier companies, in real-time through our safety management system to improve the work safety management levels. In addition, just like our employees, if any hazards are discovered on site, our suppliers’ employees can submit their suggestions through the ‘Safety Suggestion System,’ which is available within the safety management system, and then receive the results of our follow-up actions on the suggestions. The same reward system is applied to those who provide the best and most suggestions, encouraging participation in safety improvement

Strengthening Supplier Safety Capabilities

To continue our Safety Partnership with our suppliers, Hyundai steel discusses improvement measures on safety issues and shares accident cases and safety improvement activities with them through the Health and Safety Council. To establish a self-directed safety culture, we provide various systematic training courses for workers of our suppliers, including risk assessment training, basic safety courses for those new to our business sites, and experiential safety training. We are operating a safety price bidding system for contracting works to ensure that safety capabilities are fully considered when selecting suppliers, which is expected to increase the overall safety capabilities of our suppliers

Introduction of Contracting Work Safety Bidding System

Goal: Make safety a key factor when selecting a contractor to increase the contractual value of companies with strong safety capabilities

Key description: Conduct price safety bidding for qualified bidders → Select the best company based on the combined scores of Price(70 points) + Safety(30 points)

| Category | Number of suppliers |

|---|---|

| Safety Basics Evaluation | Evaluation of six items related to occupational injury rate, safety and health management system, safety and health management regulations and safety and health trainings completion of executives(conducting department: Safety and Health Division(Regularly/Frequently), Equipment Purchasing Team) |

| Safety Performance Evaluation |

Occupational safety evaluation on risk assessment, compliance with work procedures, health certifications(conducting department: Claims department) Evaluation of safety and health technical abilities, safety and health education(conducting department: Each works/Business unit’s Safety and Health Team) |

| On-site Quality Evaluation | On-site quality evaluation on project completion, progress management ability, and submitted construction documents(Conducting department: Claims department) |