Special Steel: High purity, high strength, and high durability

Achieving exceptional performance and value with specialized materials

Hyundai Steel’s special steel is an essential material used in various industries that require extreme strength and durability. It demonstrates exceptional performance in automotive engines, powertrains, heavy machinery components, and shipbuilding parts, providing enhanced performance with high-quality alloy steel that includes low levels of impurities and added alloying elements. Produced in various forms of bars, wire rods, and angle steel, it meets the specific needs of various industries and boasts excellent durability in environments that require high strength and wear resistance. Hyundai Steel has an annual production capacity of 1.5 million tons of special steel and meets the demands of global customers through rigorous quality control and technological innovation, providing optimal special steel solutions for future industries.

-

-

1.5 million tons

per year - Hyundai Steel supplies 70% of the special steel requirements and 99% of the steel grades needed by Hyundai Motor Group

-

1.5 million tons

-

- Electric arc furnace + blast

furnace hybrid production facility - Advanced dedicated manufacturing facilities for special steel ensure stable quality and supply chain

- Electric arc furnace + blast

-

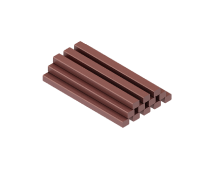

- Wide range of

steel solutions - Supplying everything from large blooms to small-sized wire rods

- Wide range of

-

- Customized

material innovation - Expanding mass production for new car models to support electrification with special steel materials and customer-oriented unique heat treatment

- Customized

Key products

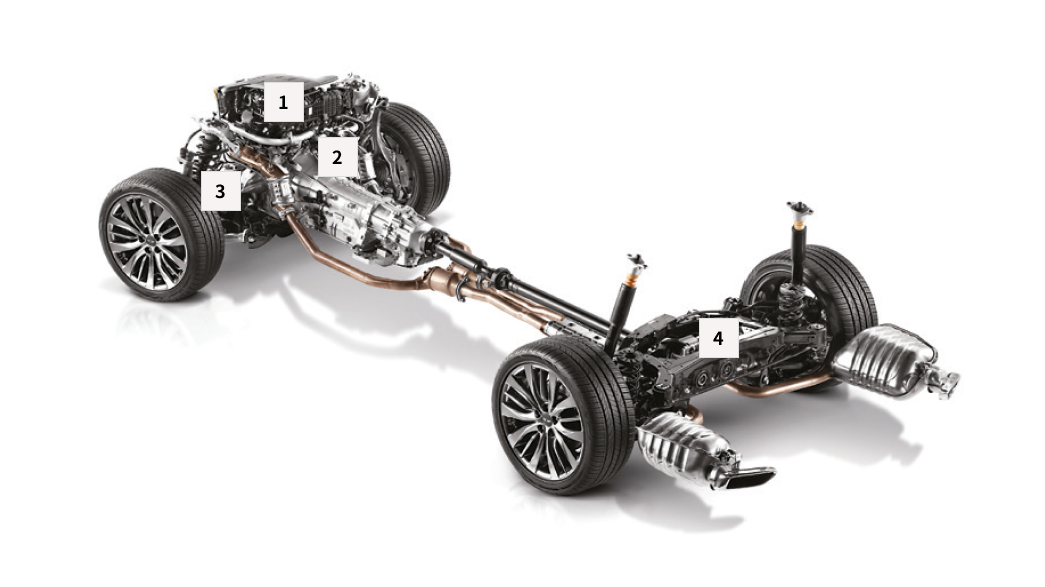

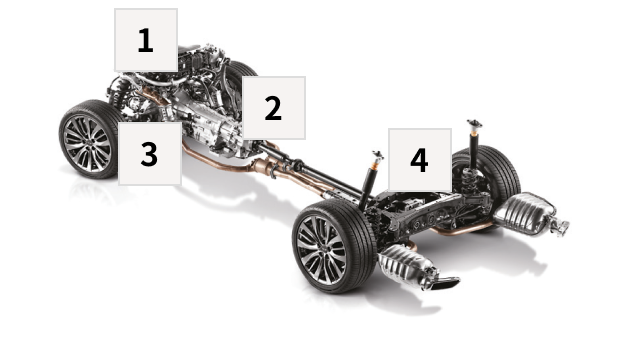

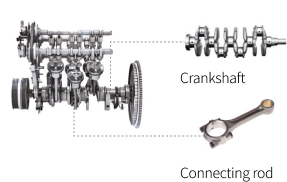

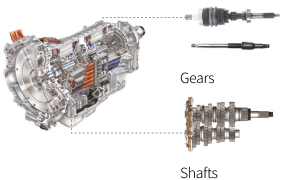

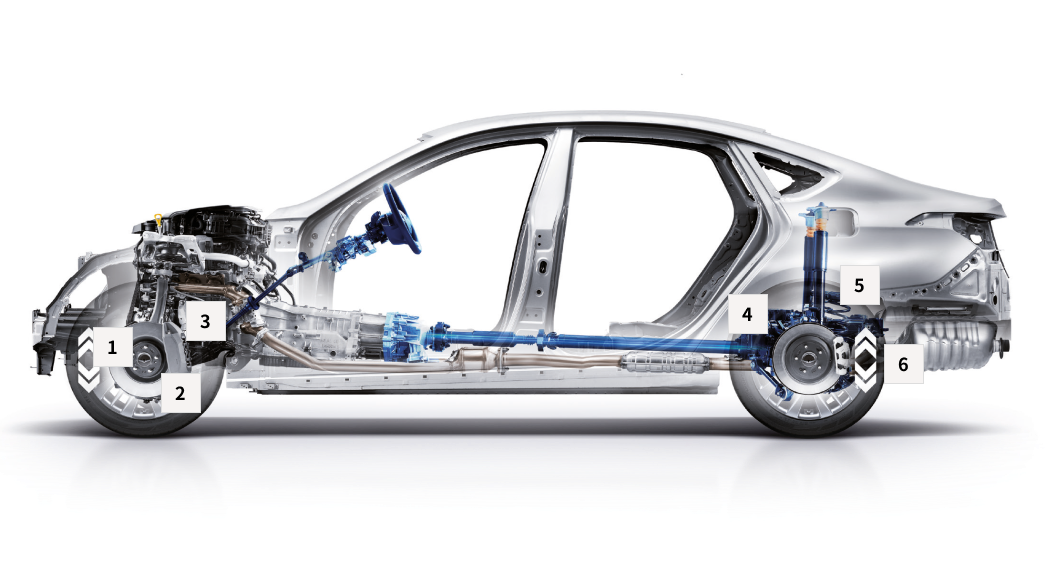

It is primarily used for components that transfer the engine’s power to the drive shaft, possessing characteristics of high strength and high durability. The types of steel vary depending on the added alloys, and they are used after processes such as forging, drawing, and heat treatment.

-

1.Engine

-

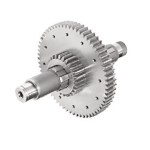

2. Transmission

-

3. Chassis

-

4. Chassis

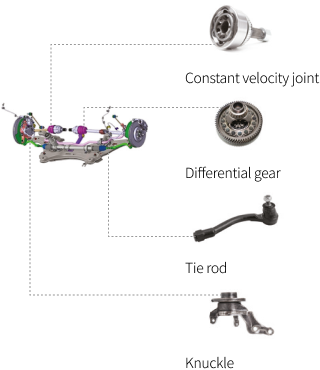

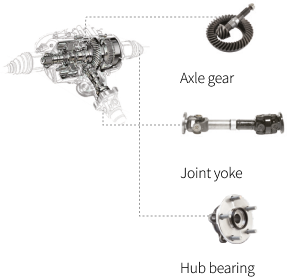

It is primarily used for components that transfer the engine’s power to the drive shaft, possessing characteristics of high strength and high durability. The types of steel vary depending on the added alloys, and they are used after processes such as forging, drawing, and heat treatment

-

1. Bearing

-

2. Drive shaft

-

3. Rack bar

-

4. Stabilizer

-

5. Coil spring

-

6. Tire cord

It is used in parts such as tractor components, employing a variety of materials ranging from alloy steels similar to those used in automobiles to carbon steels.

-

1.Axle

-

2. Engine

It is used in parts such as machine tools, employing a variety of materials ranging from alloy steels similar to those used in automobiles to carbon steels.

-

1. Key components

-

Chuck

Chuck

-

Gear

Gear

-

Cubic coupling

Cubic coupling

-

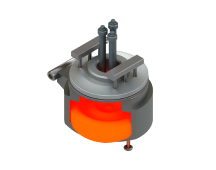

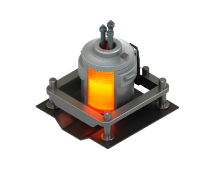

It is used not only in the engine and swivel parts of excavators but also in assembly components such as pins, bushes, and links that connect the tracks. Generally, materials with high carbon content that are highly hard and have excellent wear resistance are used.

-

1. Work device frame

-

Cylinder rod

Cylinder rod

-

Knuckle

Knuckle

-

Tooth

Tooth

-

-

2. Upper rotary body

- 1. Engine part

-

-

Engine part

Engine part

-

Connecting rod

Connecting rod

-

Rocker arm

Rocker arm

-

- 2. MCV part

-

-

Spool

Spool

-

Orifice

Orifice

-

Orifice

Orifice

-

- 3.Swivel part

-

-

Swing motor

Swing motor

-

Swing bearing

Swing bearing

-

- 4. Pinion gear

-

- 5. Ring gear

-

-

3. Lower running gear

- 1. Sprocket

-

- 2. Drive motor

-

- 3. Roller

-

- 4. Sprocket

-

- 5. Track assembly

-

-

Rink

Rink

-

Pin

Pin

-

Bush

Bush

-

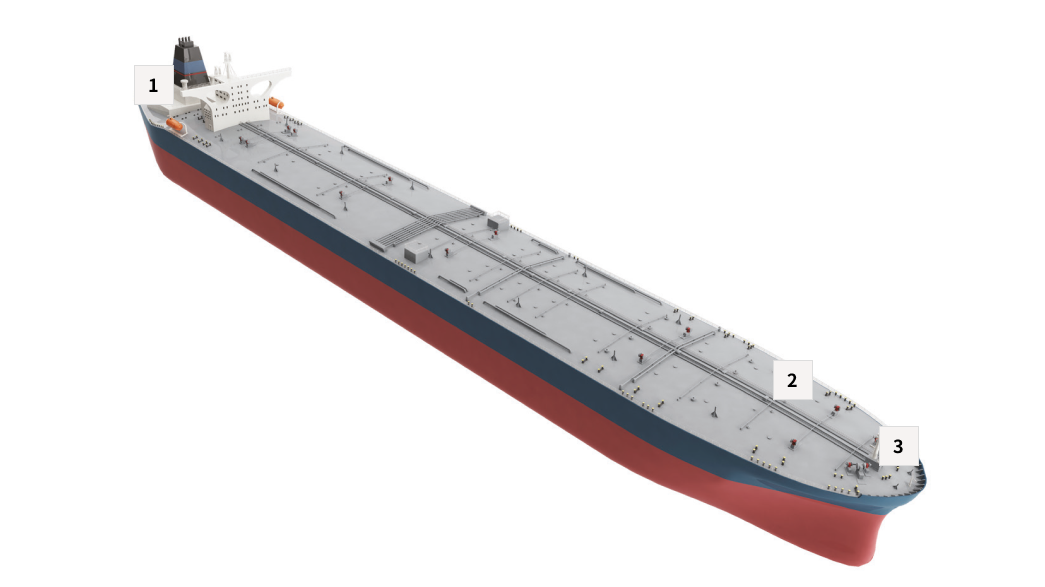

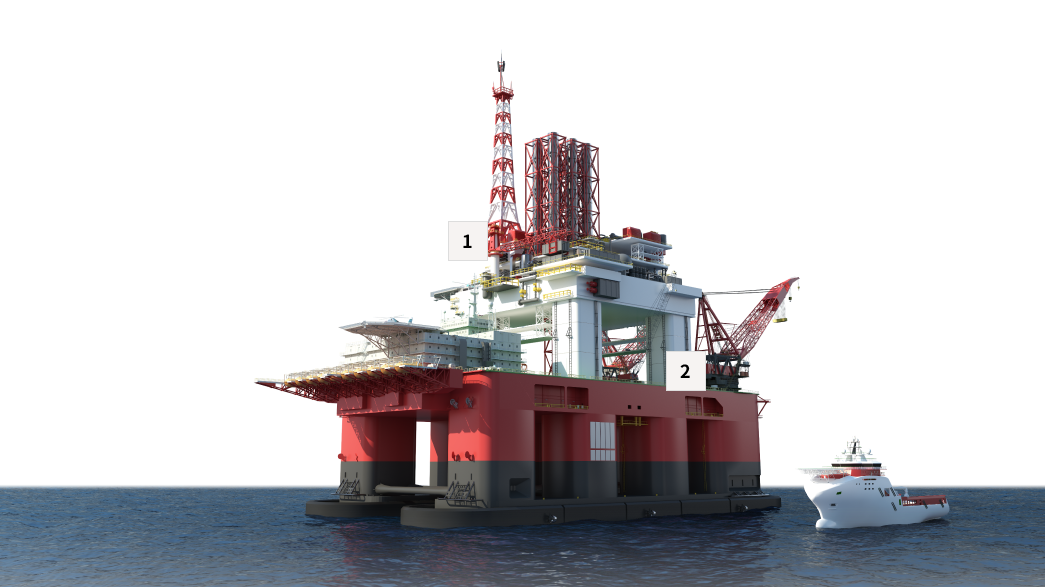

It is used in engines, shipbuilding equipment, anchor chains, etc., and materials with high hardness, corrosion resistance, and wear resistance are employed.

-

1. Engine

-

2. Shipbuilding equipment

-

3. Anchor chain

It is used in drill systems, mooring chains, etc., and materials with high hardness, corrosion resistance, and excellent wear resistance are utilized.

-

1. Drill system

-

2. Mooring chain

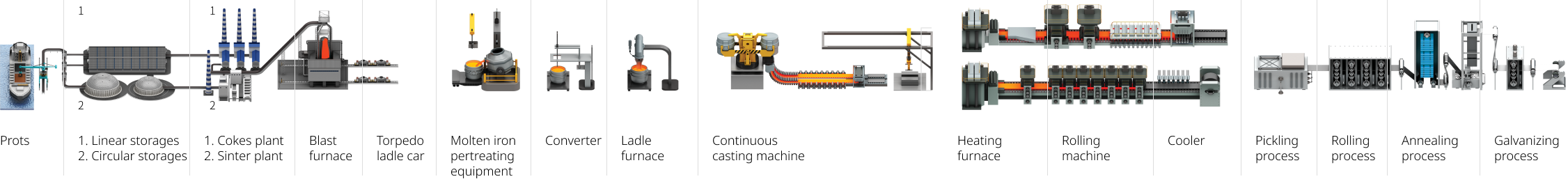

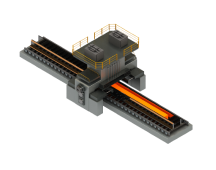

Manufacturing process

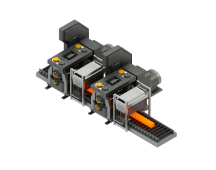

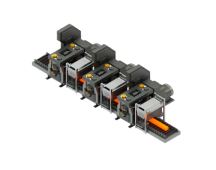

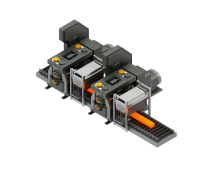

Bloom manufacturing process

-

Electric Arc Furnace

Electric Arc FurnaceProcess for producing molten steel by melting scrap and molten iron

-

LF

LFHeating of molten steel from the electric furnace and addition of iron alloy and subsidiary raw materials to adjust the composition of ingredients

-

RH

RHReflux of molten steel from the LF process in a vacuum to remove oxygen and hydrogen

-

Bloom

Bloom

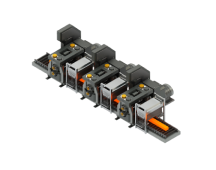

Large Bar, Billet

-

Bloom

Bloom -

Break Down Mill (BDM)

Break Down Mill (BDM) -

Continuous Mill (CM)

Continuous Mill (CM) -

Large Bar, Billet

Large Bar, Billet

Small Bar, BIC

-

Billet

Billet -

Roughing Mill (RM)

Roughing Mill (RM) -

Intermediate Mill (IM)

Intermediate Mill (IM) -

Small Bar, BIC

Small Bar, BIC

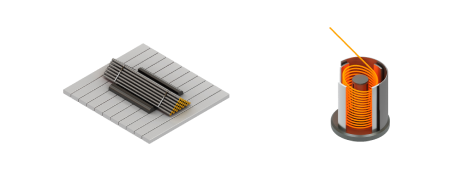

Wire Rod

-

Billet

Billet -

Roughing Mill (RM)

Roughing Mill (RM) -

Intermediate Mill (IM)

Intermediate Mill (IM) -

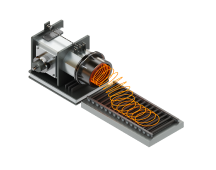

Wire Rod Mill

Wire Rod Mill -

Laying Head

Laying Head -

Wire Rod

Wire Rod

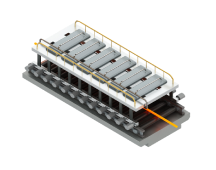

Hynndai Steel's intergrated steelworks manufacture hot-rolled and cold-rolled coils, heavy plates, pipes, and lightweight automotive parts out of iron ore and coal. By melting lumps of raw materials, molten metal is generated in blast furnaces, after which it is purified in the steelmaking process and then goes on to the continuous casting process to make slabs that can also be hardened half-finished products. Those of slabs are thoroughly rolled at a high temperature (above 1,100℃) in order to make hot-rolled coils. After that, the cold-rolled coils are made by rolling the HRC (hot-rolled coils) at room temperature to process for final usage, which is mainly for lightweight automotive parts.

Hyundai Steel’s electric arc furnace uses steel scrap to manufacture sections, reinforcing bars, and railway rails that are used for buildings, bridges and railways. After melting the steel scrap to make molten metal, it is then smelted to eliminate impurities before proceeding to the continuous casting process to manufacture halffinished products, such as blooms and billets. These half-finished products can be rolled by reheating to increase their size as finished products, such as sections and reinforcing bars, in various sizes and thickness.