Section: Key to construction structural safety

Ensuring the safety of construction structures with outstanding expertise

Hyundai Steel’s sections, with consistent cross-sections, are essential for architectural frameworks, temporary works, and civil engineering piles. Using scrap metal melted in electric furnaces, beam blanks, blooms, and billets are heated to over 1,000°C to produce H-sections, I-sections, Angles, Channels, and Sheet-piles. Known for their seismic resistance and durability, Hyundai Steel’s H-sections ensure structural safety. In addition, we supply specialized products such as steel sheet piles, which are globally recognized for their outstanding quality. As the first developer of H-sections in Korea, Hyundai Steel delivers world-class products, demonstrating leadership in the global market.

Key products

Shapes and applications

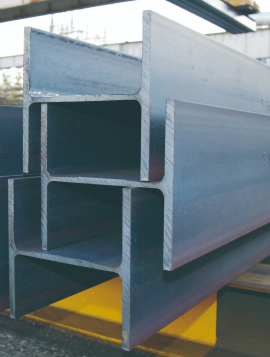

H-section

H-sections are structural steel products with an H-shaped cross-section, widely used as frameworks in large-scale constructions and civil engineering projects. Compared to welded H-sections made from hot-rolled plates, they offer superior uniformity and exceptional structural stability.

Key specifications

| KS | D 3502, D 3503(SS), D 3515(SM), D 3866(SHN), F 4603(SHP) |

|---|---|

| JIS | G 3192 |

| ASTM | A6 |

| EN | 10365 |

| AS/NZS | 3679.1 |

Angle

The Angle is a steel product with a cross-section shaped like an "L," commonly used for str uctural reinforcement in applications such as radio towers, stiffeners, and trusses.

Key specifications

| KS | D 3502 |

|---|---|

| JIS | G 3192 |

| EN | 10056-1 |

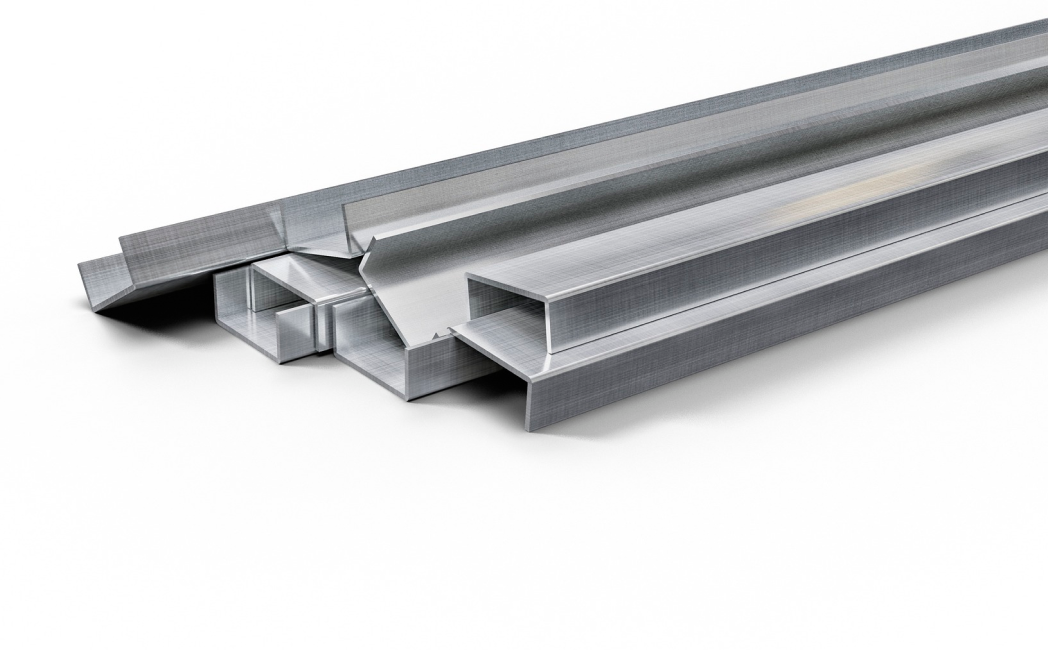

Channel

The Channel is a steel product with a U-shaped cross-section, commonly used in steel structures for industrial machine frames, braces, and trusses. It is frequently used at the joints of steel structures that incorporate H-sections or I-sections.

Key specifications

| KS | D 3502 |

|---|---|

| JIS | G 3192 |

| ASTM | A6 |

| EN | 10365 |

I-section

The I-section has an I-shaped cross-section, similar to the H-section but with a narrower flange and a thicker web. It is primarily used as running and guide rails for hoists that transport cargo.

Key specifications

| KS | D 3502, E 4002 |

|---|---|

| JIS | G 3192 |

Steel Sheet Pile

This U-shaped product is commonly used for water and soil barriers in civil engineering projects, as well as for structural foundations. The connecting sections are available in various shapes, including key-shaped and straight designs.

Key specifications

| KS | F4604(SY300, SY400, SY300W, SY400W) |

|---|---|

| JIS | A5523, A5528(SY295, SY390) |

Rail

This I-shaped steel product features a wider bottom flange compared to the top flange. It is primarily used for railway vehicle rails, offering superior strength and exceptional wear resistance compared to other section steels. These include rails designed for high-speed trains and magnetic levitation trains.

Key specifications

| Domestic Standards | 50KGN, KR60 |

|---|---|

| UIC (International Union of Railways) | UIC60 |

| High-Strength Rail | 50NHH340, 50NHH370, 60KRH340, 60KRH370 |

Steel grades

-

High-strength steel

- High-strength

- Material usage reduction

- Cost savings in construction

-

Low-temperature steel

- Ensuring resistance to low-temperature impact for polar and offshore structures

- Charpy absorbed energy specification

SM355B, C, D, SHN275/355/420/460 -

Ultra-thick large section

- Height: ~943mm

- Thickness: ~77mm

-

Specialized steel

- Specialized high-performance steel grades designed to meet the demands of specific applications

SHN (Hot rolled sections for architectural structures) SHP (Hot rolled H-sections for civil engineering structures)

Application

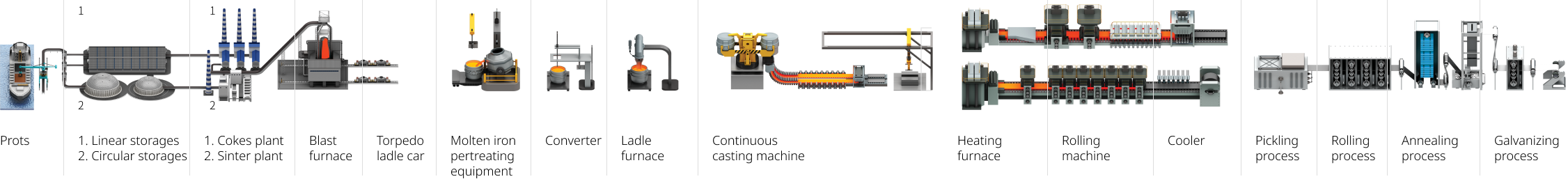

Manufacturing process

Section manufacturing process

Hyundai Steel’s section mill reheats semi-finished products to the optimal temperature in a furnace, removes iron oxide using a high-pressure descaler, and shapes them into various specifications of H-sections and general section steel using precise roughing and finishing rolling techniques.

Hynndai Steel's intergrated steelworks manufacture hot-rolled and cold-rolled coils, heavy plates, pipes, and lightweight automotive parts out of iron ore and coal. By melting lumps of raw materials, molten metal is generated in blast furnaces, after which it is purified in the steelmaking process and then goes on to the continuous casting process to make slabs that can also be hardened half-finished products. Those of slabs are thoroughly rolled at a high temperature (above 1,100℃) in order to make hot-rolled coils. After that, the cold-rolled coils are made by rolling the HRC (hot-rolled coils) at room temperature to process for final usage, which is mainly for lightweight automotive parts.

Hyundai Steel’s electric arc furnace uses steel scrap to manufacture sections, reinforcing bars, and railway rails that are used for buildings, bridges and railways. After melting the steel scrap to make molten metal, it is then smelted to eliminate impurities before proceeding to the continuous casting process to manufacture halffinished products, such as blooms and billets. These half-finished products can be rolled by reheating to increase their size as finished products, such as sections and reinforcing bars, in various sizes and thickness.