Steel Plate: Strength to withstand extreme environments

Driving competitiveness in shipbuilding and construction with exceptional strength and durability

Hyundai Steel’s steel plate comprises thick plates with a thickness of 6 mm or more, produced by hot rolling slabs followed by cooling or heat treatment processes. With an annual production capacity of 2.65 million tons and state-of-the-art facilities, we provide high-quality steel plate suitable for various industries, including shipbuilding, offshore structures, offshore wind energy, pipelines, and pressure vessels. In particular, it is a product with high strength, low-temperature toughness, and excellent weldability, delivering outstanding performance even in extreme environments. The plate certified by international classification societies such as Norway and France is recognized for its world-class quality, and continuous technological development is enhancing our competitiveness in the market.

Key products

Shipbuilding

We have received manufacturing method approvals from various classification societies and produce general-use classified steel as well as high-strength steels. In response to customer demands for higher quality and diversification due to the recent trend of lightweight ships, we possess characteristics such as high strength, low-temperature toughness, and excellent heat input welding properties. It is primarily used for the sheer strake, upper decks, hatch covers, and other components of tankers, bulk carriers, container ships, and LNG carriers.

Main specifications (strength and operating temperature)

| Normal Strength | A, B, D, E |

|---|---|

| High Strength | AH32/36, DH32/36, EH32/36, FH32/36 |

| Extra High Strength | E420, E460, E500 |

| Low Temperature | LT-FH32, LT-FH36, NV4-4, VH36-O60 |

General/Welded structures

Steel Plate for general/welded structures is expanding in use as architectural structures become larger and taller. It is mainly used in bridges, industrial machinery, buildings, and offshore wind structures.

Key specifications

| KS | SM275, SN275, SM355, HSB460 |

|---|---|

| ASTM | A36, A572, A709 |

| EN | S355J0, S355K2, S355ML, S460ML |

| JIS | SS400, SM400, SN490, SM490 |

Pipelines

With high strength, cryogenic toughness, and excellent weldability, this steel is used in the manufacturing of pipelines for the mass transportation of crude oil and natural gas.

Key specifications (API)

| Non-Sour Service | 5L-B, X42M, X52M, X60M, X65M, X70M |

|---|---|

| Sour Service | 5L-BMS, X42MS, X52MS, X60MS, X65MS, X70MS |

Pressure vessels

Steel Plate for pressure vessels is often subjected to high-pressure environments, so it possesses excellent heat and corrosion resistance. Since the applications are differentiated based on usage temperature, it is produced for high-temperature, medium-to-high temperature, and cryogenic use, and is mainly used in gas/crude oil storage vessels, boilers, heat exchangers, and power generation equipment.

Key specifications (operating temperature)

| High Temperature | A387-11-C1/C2, A387-12-C1/C2, A387-22-C1/C2 |

|---|---|

| Intermediate Temperature | A515-60/65/70, A285-C |

| Low Temperature | A516-60/65/70, A537-C1/C2, KS-SB410/480 |

| Extreme Low Temperature | A553-TY1(9%Ni), A203-D |

Application areas

Hyundai Steel’s plates boast globally recognized quality and are used as essential materials in various industries, including shipbuilding, construction, and energy. High-strength steel plate is applied in key structures such as ships, bridges, and high-rise buildings, ensuring excellent durability and safety.

Construction sector

- Safety and longevity

- Steel Plate for construction is primarily used in steel bridges, plants, and the structural components of large buildings. Moreover, in cases where it is difficult to produce standard sizes and specifications such as H-sections, Build-up Beams welded from hot rolled plates are utilized.

SS400, SM490, SM520, SN400, SN490

Hyundai Steel H COREEnergy sector

- Durability in extreme environments

- Steel Plate for plants is used in the manufacture of pressure vessels that classify, refine, and store extracted oil and gas. Pressure vessels must be able to withstand low temperatures, high temperatures, and corrosive environments depending on the type of oil or gas being processed. Hyundai Steel produces high-strength pressure vessel steel with excellent weldability, such as QT heat-treated steel, and supplies it for major projects of domestic and international energy companies.

API 5L-A, B, X60, X70, API-2H, 2W, A516-60/65, A537-C1/C2

Shipbuilding sector

- High strength durability and ultra-low temperature toughness

- Steel Plate for shipbuilding exhibits properties such as low-temperature toughness and impact resistance, and it is primarily used for bulkheads, upper decks, and hatch covers of bulk carriers, container ships, and LNG carriers. Hyundai Steel has received manufacturing method approvals from various classification societies and produces general-use classified steel as well as high-strength steels.

A, D, E, AH32/36, DH32/36, EH32/36

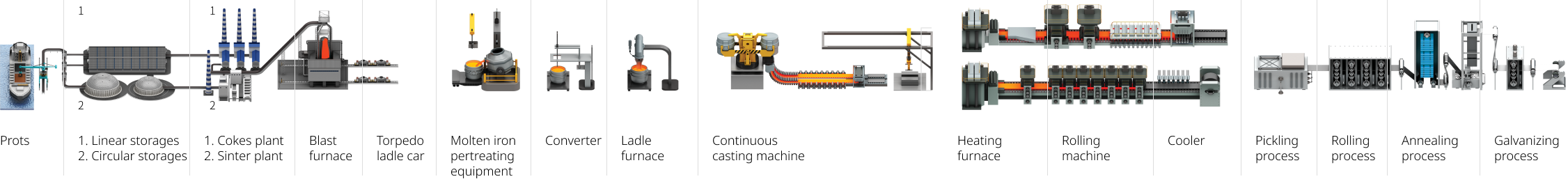

Manufacturing process

Steel Plate manufacturing process

The manufacturing process of Hyundai Steel’s Steel Plate involves processing slabs into various specifications.

The slabs are first heated in a furnace, then the surface oxides are removed using a descaler, and they are rolled to the desired thickness and width using a

roughing mill and a finishing mill. Afterwards, the plates are stabilized in quality using a cooling system and then cut to meet customer demands using

cutting machines, followed by heat treatment to enhance strength and toughness, completing the final product.

Hynndai Steel's intergrated steelworks manufacture hot-rolled and cold-rolled coils, heavy plates, pipes, and lightweight automotive parts out of iron ore and coal. By melting lumps of raw materials, molten metal is generated in blast furnaces, after which it is purified in the steelmaking process and then goes on to the continuous casting process to make slabs that can also be hardened half-finished products. Those of slabs are thoroughly rolled at a high temperature (above 1,100℃) in order to make hot-rolled coils. After that, the cold-rolled coils are made by rolling the HRC (hot-rolled coils) at room temperature to process for final usage, which is mainly for lightweight automotive parts.

Hyundai Steel’s electric arc furnace uses steel scrap to manufacture sections, reinforcing bars, and railway rails that are used for buildings, bridges and railways. After melting the steel scrap to make molten metal, it is then smelted to eliminate impurities before proceeding to the continuous casting process to manufacture halffinished products, such as blooms and billets. These half-finished products can be rolled by reheating to increase their size as finished products, such as sections and reinforcing bars, in various sizes and thickness.