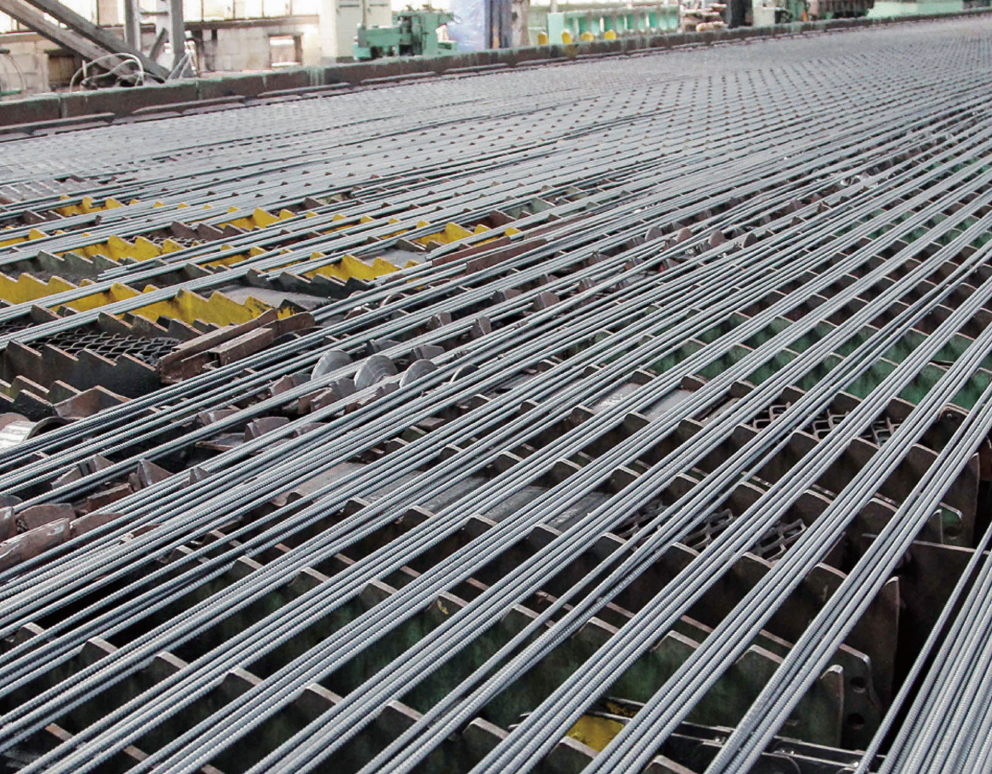

Reinforcing Bar: Foundation of architectural and civil engineering structures

Providing optimal building solutions with superior quality and seismic performance

Hyundai Steel’s rebar is engineered to maximize the safety and efficiency of buildings by offering exceptional strength and durability. The surface features longitudinal and transverse ribs, ensuring superior adhesion to concrete. This makes it an ideal choice for architectural and civil engineering applications. To meet evolving construction trends and heightened safety standards, Hyundai Steel offers customized steel grades and a wide range of specifications. Notably, its high-strength seismic steel products, such as SHN460 (H-section) and SD700S (rebar), are designed to enhance the structural stability of super-tall and large-scale structures. As South Korea’s leading producer with the largest production capacity and diverse portfolio, Hyundai Steel delivers tailored solutions to meet the unique requirements of any project. Furthermore, Hyundai Steel drives innovation in the section steel market by leveraging advanced equipment and cutting-edge techniques to develop new products and provide unparalleled customer support.

-

- Top in quality satisfaction

- Ranked No. 1 in the Rebar Category of the Korean Quality Satisfaction Index (KS-QEI)

-

- Largest portfolio

- Wide range of products with global specifications, various sizes, and diverse performances

-

- Eco-friendly product certification

- Recycling of scrap metal (GR certification, EPD certification)

-

- Customer-specific solutions

- Various steel grades, sizes, and lengths

Key products

Plain (Deformed) Rebar

This is a long steel bar with a circular cross-section and surface ribs designed to enhance bonding with concrete. These ribs improve the structural integrity of reinforced concrete by ensuring superior load transfer and increased strength. Primarily used in construction and civil engineering projects, this product plays a vital role in creating durable buildings and infrastructure. It is also one of the most widely utilized materials in modern construction.

Key specifications

| KS | D 3504 |

|---|

Ultra-High Strength Rebar

This high-performance rebar delivers a yield strength exceeding 500 MPa, making it ideal for demanding applications such as super-tall buildings and long-span bridges. With the growing focus on advanced infrastructure and resilient construction, demand for this product has been steadily rising.

Key specifications

| KS | SD500, SD600, SD700 |

|---|

Threaded Rebar

This product differs from plain rebar by featuring spiral ribs instead of longitudinal ones, providing enhanced bonding strength with concrete. By utilizing specialized couplers for assembly, it significantly improves cost efficiency and structural stability. These features make it an ideal choice for high-rise buildings, particularly in applications requiring pre-assembly and post-installation.

Key specifications

| KS | SD500, SD600, SD700 |

|---|

Seismic Reinforcement Rebar

This product differs from plain rebar by having a controlled upper strength limit, which ensures predictable performance under extreme conditions. During an earthquake, it is designed to deform as intended by engineers, maintaining the structural integrity and enhancing seismic performance. With its exceptional elongation capacity, this product is widely utilized not only in seismic-resistant designs but also in a variety of other structural applications.

Key specifications

| KS | SD400S, SD500S, SD600S, SD700S |

|---|

Weldable Rebar

This product is specifically engineered with optimized carbon content and carbon equivalent (CEQ) to enhance weldability. It is ideal for rebar splicing in structures where reliable welding performance is critical.

Key specifications

| KS | SD400W, SD500W |

|---|

Application

Manufacturing process

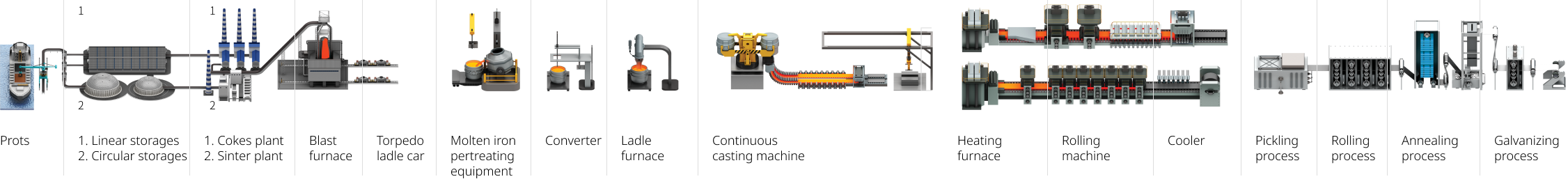

Rebar manufacturing process

At Hyundai Steel’s rebar plant, semi-finished products are precisely heated in advanced natural gas furnaces to optimal temperatures. They then undergo a meticulous rolling process, including both rough and finishing stages, to produce rebar in a wide range of specifications tailored to industry needs.

Hynndai Steel's intergrated steelworks manufacture hot-rolled and cold-rolled coils, heavy plates, pipes, and lightweight automotive parts out of iron ore and coal. By melting lumps of raw materials, molten metal is generated in blast furnaces, after which it is purified in the steelmaking process and then goes on to the continuous casting process to make slabs that can also be hardened half-finished products. Those of slabs are thoroughly rolled at a high temperature (above 1,100℃) in order to make hot-rolled coils. After that, the cold-rolled coils are made by rolling the HRC (hot-rolled coils) at room temperature to process for final usage, which is mainly for lightweight automotive parts.

Hyundai Steel’s electric arc furnace uses steel scrap to manufacture sections, reinforcing bars, and railway rails that are used for buildings, bridges and railways. After melting the steel scrap to make molten metal, it is then smelted to eliminate impurities before proceeding to the continuous casting process to manufacture halffinished products, such as blooms and billets. These half-finished products can be rolled by reheating to increase their size as finished products, such as sections and reinforcing bars, in various sizes and thickness.